Check Order Status

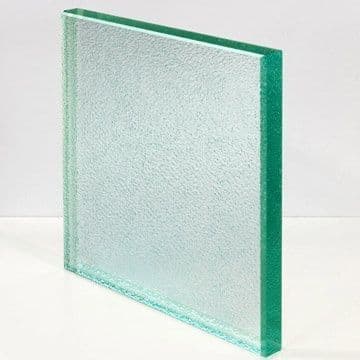

Clear Glass

What is clear glass?

Also known as annealed, heavy, or plate glass, is transparent in nature with a slight green or blue tint due to the iron impurities in the sand used during manufacturing. The clear and see-through quality makes it suitable for windows, doors, mirrors, and furniture like tables and shelves at home. It can also be used for kitchen splashbacks, glass dining tables, shower screens, wardrobe doors, mirrors, and DIY glass sheet projects.

When it comes to commercial places, it is what you often find in windows and doors. This kind of glass is so commonly used because of its clarity which allows natural light to pass through, allowing a wide variety of applications.

Customizable Options for Clear Glass

It’s quite simple. Choose a shape, enter your measurements, select your favorite glass tint, thickness, strength, edge style, etc., and check out your custom-designed clear glass.

What are the applications of clear glass?

With a multitude of applications owing to its transparent and versatile nature, this type of glass makes an ideal material for windows, glass tables, lenses, and mirrors, where transparency is essential. Frequently used for round glass tables, adding an elegant touch and enhancing the visual appeal with the transparency of the glass. It also offers insulation properties and can be recycled without compromising quality, making it an environmentally friendly option.

The cost-effectiveness and adaptability of this type of glass contribute to its popularity in both commercial and residential projects. In homes, it is commonly utilized for windows, doors, mirrors, and furniture like tables and shelves. The versatility extends to various applications such as partitions, staircases, balustrades, balconies, and shower cubicles in both residential and commercial settings.

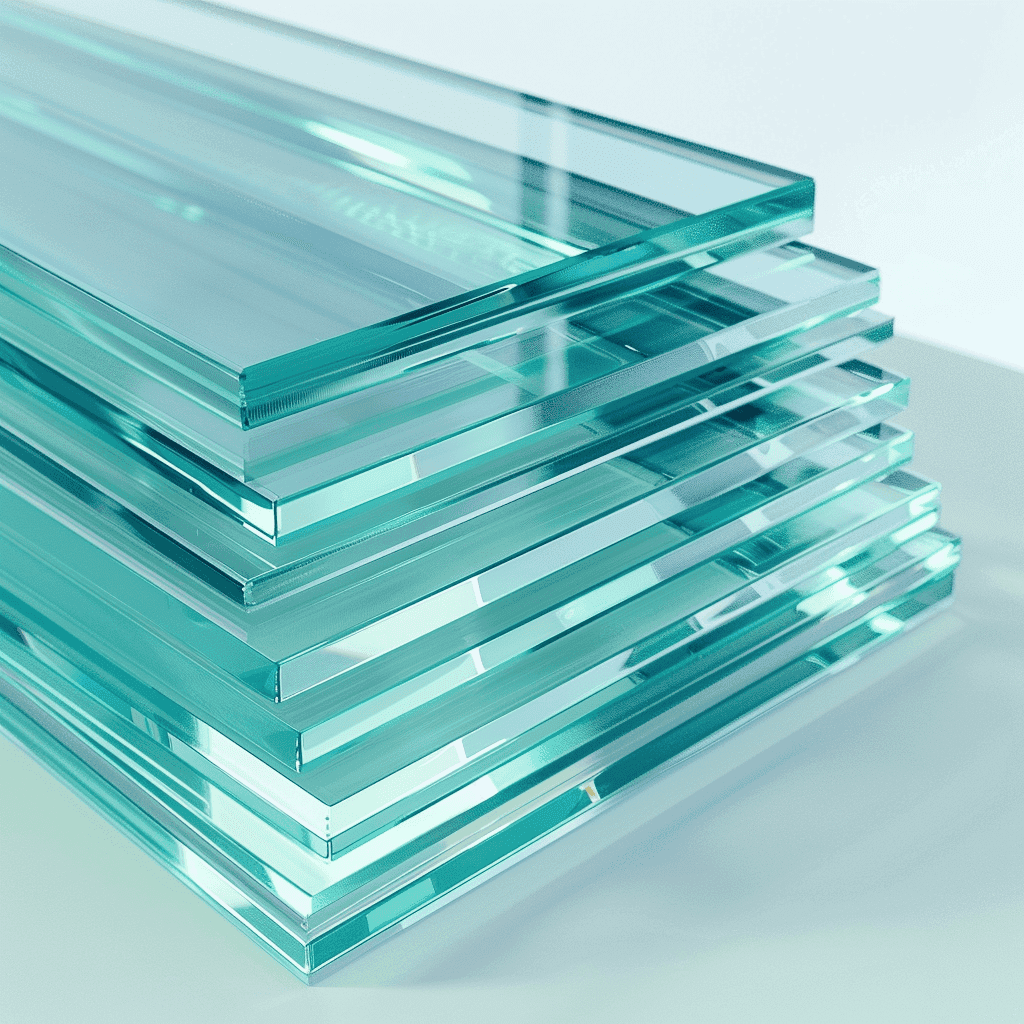

What is the thickness of clear glass?

Choosing the right glass thickness is key for various projects, and it depends on the specific applications and purposes.

- 3/32" (2.4 mm) For picture frames and small insulated glass units, although it can't be tempered.

- 1/8" (3.2 mm) For small cabinet door panels, insulated units, and coffee table glass

- 3/16" (4.8 mm) Picture frame, living room table tops, and door lites.

- 1/4" (6.4 mm) Larger cabinet door panels, shelves, and framed shower doors.

- 3/8" (9.5 mm) Glass partitions, panels, dining room glass table tops, and larger projects.

- 1/2" (12.7 mm) Larger applications like countertops and glass walls.

- 3/4" (19.1 mm) or 1" (25.4 mm) For extensive projects such as glass floors, railings, or mall fronts.

Ultimately, the choice of glass thickness is determined by the specific needs and applications of each project, ensuring both functionality and aesthetic considerations are met.

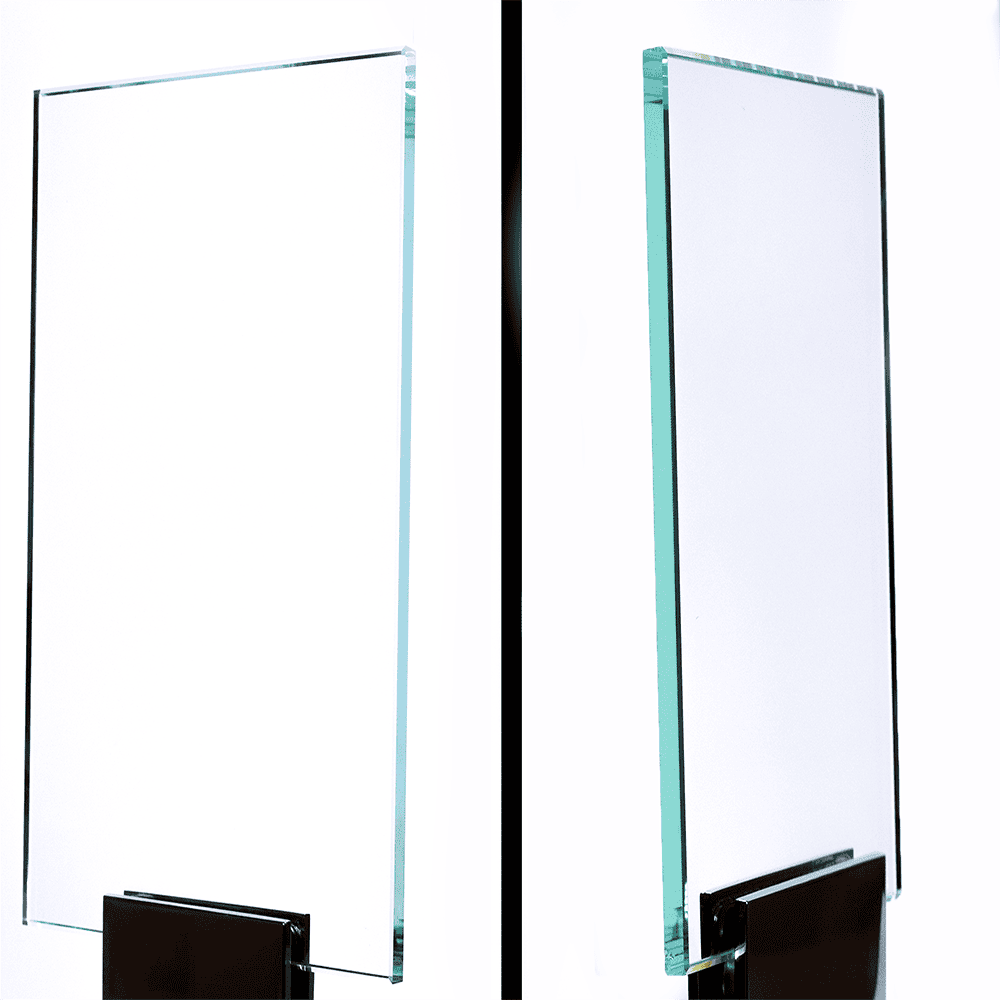

Standard Clear Glass vs. Low-Iron Glass

When comparing annealed glass with low-iron glass, the big difference is how much clearer the latter is. Low-iron glass is great for things like frameless glass walls, display cases, and small space partitions because of its superior transparency. Annealed glass tends to have a bit of a blue-green tint due to more iron content, which is a downside if you're aiming for clarity and aesthetics. The tint can make thicker pieces look almost black at the edges.

On the flip side, low-iron glass has almost no tint, giving you a clean slate for color-matching and a more appealing look. It also has better light transmission than an annealed glass sheet, making it ideal for applications where a clear view is essential. Just keep in mind that the light transmission isn't perfect in low-iron glass, especially in thicker cuts, but it still outshines regular glass in this department. All in all, low-iron glass brings more clarity and brightness to the table, making it the top pick for situations where an unobstructed view matters.

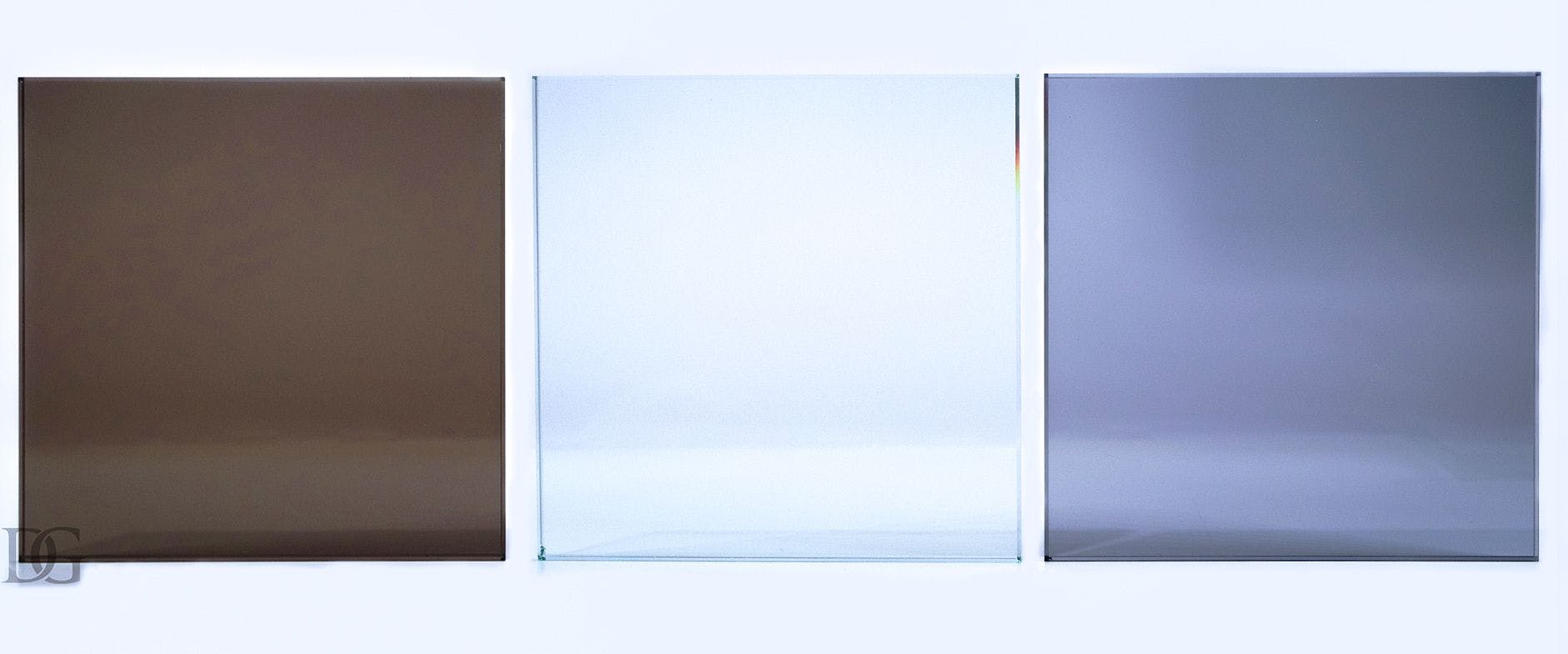

What is the difference between tinted and clear glass?

Tinted glass is designed to reduce the amount of light transmitted and absorb solar energy, leading to heat absorption. While this can help reduce glare and sunlight entering a room, it may also result in thermal stress, potentially causing breakage if the glass is not tempered. Tinted glass is great for rooms with direct sunlight, contributing to reduced solar heat, lower energy bills, and increased energy efficiency. On the other hand, clear annealed glass is preferred when maximum clarity is desired. It's important to note that laminated and toughened varieties offer enhanced strength compared to tinted float or annealed glass. Although tinted glass is generally more expensive, its ability to reduce heat transmission makes it a valuable choice for those looking to enhance both comfort and energy efficiency in their living spaces. To know more about tinted glass, visit our blog in this link.

What is the importance of clear glass?

Annealed glass is a crucial material in homes and industries, offering versatility and aesthetic appeal. In home settings, it finds versatile applications, enhancing living rooms with its use in coffee tables and glass dining tables. Its transparent nature allows for an abundance of natural light, contributing to well-lit and inviting atmospheres. In industrial applications, glass sheets are often utilized for safety shields, windows, railings, doorways, and skylights, ensuring visibility without compromising safety protocols.

What are the cons of clear glass?

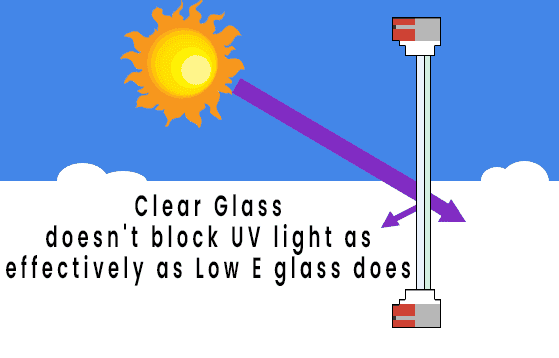

Traditional glass has its downsides, mainly showing a slightly hazy and faint tint of green-blue even in ideal conditions. Thicker pieces might have stronger color concentration at the edges, and the chemical composition limits how light penetrates. A significant disadvantage though, is that it doesn't block UV light as effectively as Low E glass does, impacting both clarity and privacy since it allows more external visibility into spaces.

Help & Installation Videos

Not sure where to start? We’ve put together a series of helpful videos for you.

More Helpful Tips

From how to clean table tops to unique DIY projects for tables with glass tops. We have a collection of helpful tips for you!

Need Expert Help?

Buy in Bulk

Become a Dulles Glass PRO

Clear Glass FAQs

Regular annealed glass isn't that durable on its own. To make it stronger and safer, it has to go through a toughening process like tempering, chemical strengthening, or thermal processing. Just like any other regular glass; it can break easily and needs to be properly handled to avoid damage. Unlike tempered or toughened glass, when regular glass breaks, it shatters into sharp pieces.

Also referred to as annealed or standard glass, is the type commonly found in windows and commercial doors. It stands out as one of the most prevalent commercial glass varieties. Annealed glass, considered a basic glass, is frequently utilized for windows and doors due to its transparency, allowing ample natural light to enter. This type of glass can come in a clear form, providing flexibility in design choices for various applications.

Also referred to as annealed, is manufactured through a meticulous chemical process involving a combination of raw materials such as Silica, Soda, and Lime. These ingredients are subjected to high temperatures, undergoing a fusion until they melt into a liquid form. Next is the cooling process, wherein the molten glass is placed on a mold, usually over a bed of molten metal, commonly tin. This floating process allows the glass to spread evenly, forming a smooth and clear surface as it cools and solidifies. This kind of practice is usually done by commercial producers.

The strength of clear annealed glass depends on a few factors: glass thickness controls the glass strength and as expected, thicker glass is stronger than thinner glass. Depending on the application an upgrade to thicker glass may be necessary. Another factor impacting the strength of the glass is whether it has been tampered with or not. Raw glass that has been through a tempering process is generally 5x stronger and sometimes referred to as toughened glass.

Certainly! Tempering is a specific heat treatment process used to strengthen glass. The transformation involves a carefully controlled tempering process. In this process, the annealed glass is first heated to a high temperature and then rapidly cooled using forced air. The rapid cooling, typically achieved through quenching, induces surface compression and internal tension in the glass, enhancing its strength and making it more resistant to breakage. Tempered glass is commonly used in applications where safety is a priority, as it shatters into small, less harmful pieces upon breaking. This quality makes it a popular material for use in dining room tables.

In its raw format is also called annealed and is not the same as tempered glass. It can go through a tempering process that would make it approximately 5x stronger than annealed glass. The increased strength enables tempered glass to withstand significantly more pressure before shattering. Learn more about tempered glass by visiting our blog at this link.

Customization At Its Best

Whether your project is just getting started or needs help to find the final touch, our glass and design experts are here to help you make your dreams come true.

Fast & Free Shipping

Nationwide free shipping on your entire order, delivered within 3 - 7 days. Guaranteed to arrive in one piece!

Expert Customer Service

Our friendly team is here for you 7 days a week. Call, email, text or live chat with us.

Best Deals & Rewards

Prices that fit your budget and amazing deals and rewards to maximize your savings.

Our customers say

Excellent

4.9 out of 5 stars

Dulles Glass

Company

Support

United States © 2025 Dulles Glass. All Rights Reserved.