Check Order Status

Tempered Glass

Tempered Glass

Tempered Glass is made from annealed glass via a thermal tempering process. The meticulous manufacturing process makes it stronger and safer to use especially across several industries, particularly in doorways, glass tops, and shower enclosures where it meets mandatory federal safety standards. Whether it’s for a commercial or residential project, tempered glass showcases the perfect fusion of strength, safety, and aesthetic appeal, making it a reliable choice. In this article, we take an in-depth look at tempered glass.

Customizable Options for Tempered Glass

It’s quite simple. Choose a shape, enter your measurements, select your favorite glass tint, thickness, strength, edge style, etc., and check out your custom-designed replacement glass.

How is Tempered Glass Made?

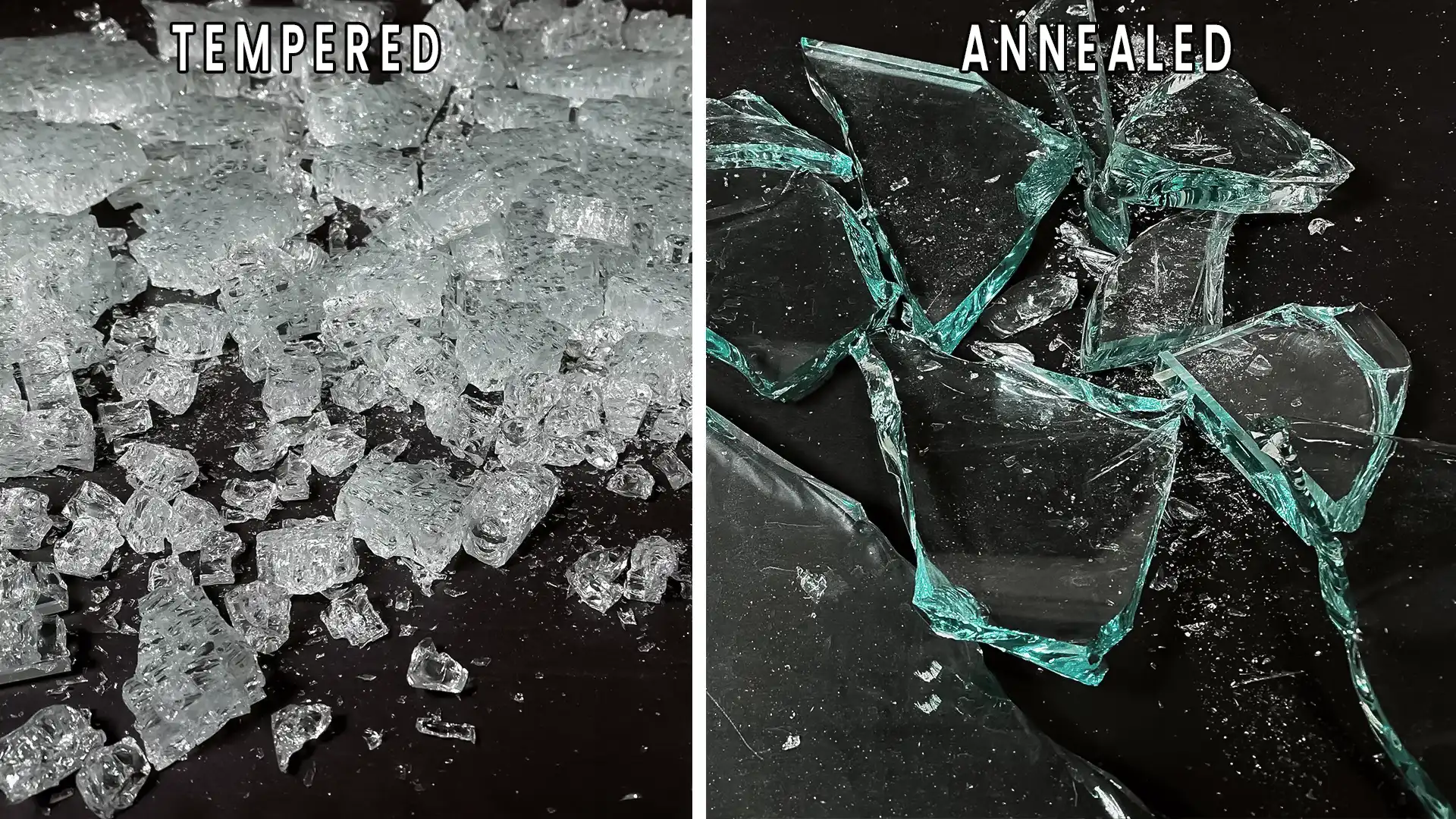

Tempered glass is made by heating an annealed glass sheet at a high temperature and then cooling down at a rapid pace. This process compresses the glass while maintaining tension in its core. Tempering induces a stress pattern in the glass, enhancing the mechanical strength of tempered glass to be up to 5x greater than that of annealed glass. Upon breakage of tempered glass, the accumulated energy from the stress pattern is rapidly released, causing the glass to fracture into tiny, pebble-like pieces.

Tempered Glass vs. Annealed Glass

Annealed glass also known as “float glass” is produced in large sheets in a float line. Annealed glass undergoes a slow regulated cooling process. The gradual cooling process does not produce internal tension, allowing it to be cut, fabricated, and polished. Annealed glass can break into large pieces or shards that can cause serious injury.

Tempered glass is float glass that has been treated by using heat followed by a rapid cooling process until it reaches a certain strain point. Tempered glass breaks into much smaller fragments of glass. Tempered glass is 5x more durable compared to annealed glass. Once annealed glass has been tempered further cutting, fabrication, or size adjustments cannot be done such as cutting, drilling a hole, or polishing.

Is Tempered Glass Breakable?

Yes, tempered glass is breakable! While tempered glass is significantly stronger compared to annealed glass, it is still not entirely immune to breakage. The most vulnerable parts of glass after it has been tampered with are the corners, next are the edges, then the surface. A strong impact with certain materials such as iron, steel, stone, or masonry on the corners or edges of the glass can result in the breakage of the glass. A sharp impact on the surface of the glass such as a diamond, carbide, or steel can also cause breakage. Other factors that could lead to tempered glass breakage are chips, nicks, high impact, thermal stresses, and extreme heat. While tempered glass is breakable, once broken it would break into small pieces that would normally not cause life-threatening injuries.

Is it better to use Tempered Glass?

Here at Dulles Glass, we recommend most glass products be tempered before being used for its application. While for some applications it is mandatory by codes and laws to use safety glass, the new processes in tempering have made it so much easier and cost-effective to add this extra safety all the time. Tempering glass does not adversely affect the appearance of the glass.

Tempered glass brings more to the table than safety; it is stronger than plate or annealed glass and serves as a protection that makes the glass a little more resistant to damage, thus, making it great for high-traffic areas. Its ability to withstand heat variations expands its usability whether it's for a residential or a commercial setting. It's been widely used in cooktop screens, oven doors, glass tops, doorways, windows, shower doors, and glass panels.

Types of Tempered Glass that can be tempered:

Most types of plate or annealed glass of different thicknesses and sizes can be tempered except for cases where the makeup of the glass or an application that has been applied to the glass cannot withstand the heat of a tempering oven or the rapid cooling "quenching" process. For example, a mirror cannot be tempered since the silvering of the mirror would not withstand the heating process, this also applies to some patterned glass types, painted glass, very thin glass, and laminated glass. Glass needs to be tempered before paint or laminating film is applied, however, some types of paints can be applied before the tempering process. The maximum size of the glass that can be tempered depends on some factors like the size of the tempering oven, glass type, thickness, and the number of cutouts on the glass. In general, the minimum sizes that can be tempered are about 3x7”, and the maximum sizes are about 74x130”.

Is Tempered Glass good for showers?

Yes, tempered glass is the material of choice when it comes to frameless shower doors. The recent advances in the glass hardware and glass tempering process have given the freedom to use glass in the shower enclosure area. The reason why glass is a preferred option for showers is its versatility in transparency and privacy, allowing light in while keeping steam and hot water inside the showering area. Using tempered or safety glass is also required by US construction codes. Each glass panel must carry a tempered “bug” to certify its safety.

Where to use Tempered Glass?

Tempered glass is widely used for its strength and safety features. It's utilized for both residential and commercial applications like glass panels, dividers, clerestory glass, shower enclosures, partitions, glass doors, and many more. In showers, it ensures durability and safety. Tempered glass panels for windows and partitions let more light in by allowing the glass to be used in many places where glass could not be used in the past, providing an aesthetic appeal. Shelves made from tempered glass offer a modern look with sturdiness. For table tops, its impact resistance makes it a practical and stylish choice in various settings.

Tempered glass vs. Laminated glass

Laminated and Tempered glass serve similar, yet distinct purposes based on intended use, placement, and safety requirements. Both can be used as safety glass however: when glass will be used overhead such as in balconies, skylights, canopies, floors, and/or stairs laminated glass is usually required by building codes. It is also used when a design or pattern is desired inside the glass for custom displays and feature walls. Laminated glass is crafted by bonding two or more layers of glass with different types of interlayers, creating a robust structure that resists breaking apart.

It is the PVB layer that holds the glass together. Should one of the glass panels be broken, the interlayer would hold the broken layer of glass together with the other layer(s) making it much less likely to fall. On the other hand, tempered glass undergoes a tempering process, that while offering strength and resistance to force, can come apart if broken. Tempered Laminated glass is often an option where these two types of glass can complement each other with their strengths. By Laminating Tempered Glass into multiple layers, greater structural strength is gained while increasing the safety and integrity of the panel. Tempered glass is a more cost-effective option when not being used overhead as a canopy, skylight, floor, or stair glass.

Discover additional insights about laminted glass on our blog.

Help & Installation Videos

Not sure where to start? We’ve put together a series of helpful videos for you.

More Helpful Tips

From how to clean table tops to unique DIY projects for tables with glass tops. We have a collection of helpful tips for you!

Need Expert Help?

Buy in Bulk

Become a Dulles Glass PRO

Tempered Glass FAQs

No, tempered glass by its nature will break upon any attempt to cut it or drill into it. Tempered glass has a hard outer surface holding together a softer inner surface. If the outer surface is compromised the glass will break into small pieces as intended. If modifications are needed, they must be done before the tempering process.

Absolutely, tempering glass is unquestionably worthwhile, especially in applications where strength, safety, and thermal resistance are paramount. When glass undergoes tempering, its overall strength, thermal shock resistance, and safety characteristics are significantly enhanced.

Tempered glass prices vary based on the glass types, glass thickness, and the volume of the purchase. Here at Dulles Glass, we provide a convenient solution for estimating the cost of tempered glass. Our innovative AI tool allows you to input the size of the tempered glass you need and you can easily obtain an estimated cost tailored to your specific dimensions. This approach ensures both ease and convenience in determining the price, as it takes into account the unique factors that influence the cost of tempered glass.

Tempered glass is designed to withstand high temperatures, making it a suitable choice for various applications. As a general rule, if the temperature does not exceed 290 ºC and there is no rapid change in temperature over 150 ºC, tempered glass is unlikely to break. This resilience makes it reliable for withstanding heat, eliminating concerns about a hot serving dish being too hot when placed on a glass tabletop.

Plexiglass is not actually glass and is usually a type of plastic or acrylic, so it differs from tempered glass in several key aspects. Unlike tempered glass which is treated to resist breaking into large dangerous shards upon impact, plexiglass can crack or break into larger pieces. These differences affect its usage and durability in different scenarios. Plexiglass is known for being lighter and is sometimes used as an alternative to tempered glass. However, it's essential to note that the softer plastic nature of plexiglass makes it more prone to scratches. Acrylic or plexiglass is also less resilient to direct sunlight/UV rays, and extreme temperatures and since it's a petroleum-based product, petroleum solvents, chemicals, etc. will leave marks or stain the surface. This can be a significant concern for homeowners with pets and small kids. Despite these considerations, plexiglass is valued as an alternative to tempered glass, especially when its distinct characteristics suit specific project needs.

The difference in appearance to the naked eye between tempered glass and annealed or plate glass is almost nonexistent. To figure out if the glass is tempered, the first and easiest way to recognize tempered glass is by checking to see if the glass has a tempered bug or stamp on it. Tempered glass typically carries a permanent certification label or logo. Tempered glass fabricators are legally required to affix a label on the tempered glass unless the customer explicitly opts out of having a label. You'll find this label near a corner of the glass panel, indicating that the glass meets safety requirements set by testing and regulatory agencies. Look for a printed or carved symbol on the glass, which shows the manufacturer's name and confirms compliance with SGCC standards. This stamped symbol also called ‘’temper bug” acts as solid proof that the glass has gone through the tempering process.

Another way to tell is to check for strain patterns or roller waves. For strain patterns look through the glass at different angles with light behind it, if you see very faint patterns through the glass these occur naturally during the tempering/quenching process. Roller waves can be found using a straight edge on the flat surface of the glass. A very slight wave pattern on the glass surface would indicate a roller wave; another thing that naturally occurs during the tempering process.

The process of glass tempering is irreversible. Before tempering, measurements need to be accurate with absolutely no doubt, any required alterations such as polishing, grinding, or drilling holes must be meticulously executed, as the glass cannot be manipulated once tempered. Despite its enhanced durability, tempered glass is not impervious to damage. Although tempered glass is designed to be more robust than regular glass, it’s still susceptible to breakage.

Tempering can be applied to various glass types, opening up a range of possibilities for customization to suit different purposes. Whether it's your standard clear glass or tinted, patterned, or even reflective glass, the tempering process enhances strength and safety without compromising the unique characteristics of each type. It's important to note that if the glass has had a film, coating, or any PVB applied to it that can not be tempered, this includes glass mirrors, back-painted glass, and laminated glass.

The standards for tempered glass are outlined in the industry specifications, primarily governed by ASTM C1048. These specifications pertain to heat-treated or tempered glasses, establishing the criteria for their production.

For heat-strengthened glass, the requirements include achieving a surface compression falling within the range of 3,500 to 7,500 psi. Notably, there is no specific requirement for edge compression in the case of heat-strengthened glass. It's important to note that glass thickness ranging from 1/8” through 3/4” is suitable for tempering.

By the International Residential Code (IRC), tempered glass is mandated in specific locations around residential properties deemed hazardous. The code outlines several scenarios where the use of tempered glass is required: including but not limited to glass next to walkways and ramps, doors, shower enclosures, guards and rails, stairs and ramps, certain windows, and wherever safety is a priority.

Tempered glass is available in a range of sizes, determined by the thickness of the glass. Generally, glass thickness ranging from 1/8 inch to 3/4 inch can undergo the tempering process.

Dulles Glass offers a wide range of tempered glass thicknesses, these are as follows:

1/8, 1/4, 3/8, 1/2, and 3/4

Dulles Glass can temper most glass thicknesses up to 74” by 130”, however the maximum size of 1/8” thick glass is 50” by 50”. For larger sizes please contact us.

Tempered glass table tops are notably stronger than annealed glass, providing superior protection for furniture. With its elegance, sophistication, and easy maintenance, glass tables have become focal points in contemporary homes. Additionally, the dense and non-porous nature of tempered glass shields it from the effects of humidity, ensuring it has an avant-garde look over time. The mechanical properties, luster, and high-temperature resistance make tempered glass tables a reliable and safe choice. The variety of colors, patterns, and shapes further caters to diverse consumer preferences, making tempered glass an all-around practical and stylish option for table tops.

The difference between tempered glass and laminated glass in skylights lies in their safety features, soundproofing abilities, security aspects, cost, and energy efficiency. Skylights fitted with tempered glass are considered safe as the glass breaks into small, non-sharp pieces upon impact, facilitating easier cleanup. On the other hand, laminated glass skylights offer superior soundproofing and an added layer of safety as the glass stays intact even after breaking. Most skylights are best tempered and laminated.

Most exterior doors are made with tempered glass as a safety measure to minimize the risk of breakage and potential injury. Both exterior and interior glass doors, including sliding glass doors for patios and showers, are constructed with safety glass, either tempered or laminated, in compliance with residential building codes. This requirement ensures that the glass in exterior doors and most windows are stronger and more durable than the glass found in everyday kitchenware. The use of tempered glass in exterior doors enhances their resilience and safety, aligning with established standards to provide homeowners with a secure and robust entry point.

Placing an order for your customized tempered glass is a straightforward process. Simply visit the tempered glass page, where you can easily navigate through the options. Choose the desired shape, input your specific measurements, and proceed to make selections for the glass type, edge, and corner work, as well as the preferred glass thickness. The user-friendly interface ensures a seamless ordering experience, allowing you to customize the tempered glass to your exact specifications with just a few simple clicks.

The turnaround time for shipping at Dulles Glass varies depending on the items purchased and the specific delivery methods available for each item. For in-stock products, the delivery typically takes place within 1 business day. However, custom products are shipped within 1-3 business days.

Certainly! Our team at Dulles Glass is dedicated to assisting in the customization process. Whether you have technical or design-related questions, feel free to reach out to us through live chat, email (info@dullesglass.com), or by calling us at (866) 452-7707. We're here to ensure a smooth and tailored experience for your new glass purchase.

Customization At Its Best

Whether your project is just getting started or needs help to find the final touch, our glass and design experts are here to help you make your dreams come true.

Fast & Free Shipping

Nationwide free shipping on your entire order, delivered within 3 - 7 days. Guaranteed to arrive in one piece!

Expert Customer Service

Our friendly team is here for you 7 days a week. Call, email, text or live chat with us.

Best Deals & Rewards

Prices that fit your budget and amazing deals and rewards to maximize your savings.

Our customers say

Excellent

4.9 out of 5 stars

Dulles Glass

Company

Support

United States © 2025 Dulles Glass. All Rights Reserved.